-

Table of Contents

Simulating Real-World Systems for Optimization

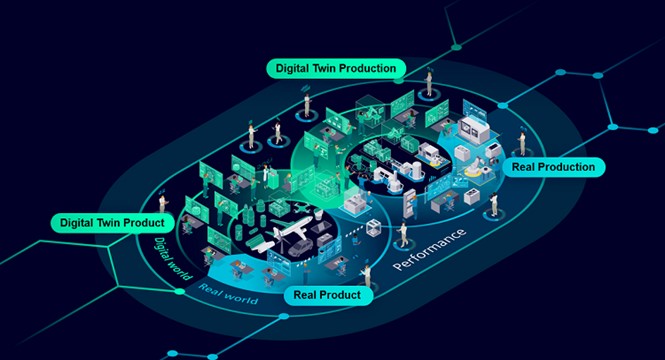

Digital Twin Technology is a cutting-edge concept that involves creating virtual replicas of real-world systems, such as machines, products, or even entire cities. These digital twins are created by combining data from various sources, including sensors, IoT devices, and historical data. By simulating real-world systems, digital twin technology enables organizations to optimize their operations, improve efficiency, and make informed decisions. This technology has gained significant traction in industries such as manufacturing, healthcare, and transportation, offering immense potential for innovation and growth.

Enhancing Industrial Processes with Digital Twin Technology

Digital Twin Technology: Simulating Real-World Systems for Optimization

In today’s rapidly evolving technological landscape, industries are constantly seeking innovative ways to enhance their processes and improve efficiency. One such technology that has gained significant attention is digital twin technology. Digital twin technology involves creating a virtual replica, or “twin,” of a physical system or process, allowing for real-time monitoring, analysis, and optimization.

The concept of digital twin technology is rooted in the idea of bridging the gap between the physical and digital worlds. By creating a virtual replica of a real-world system, businesses can gain valuable insights into its performance, identify potential issues, and make informed decisions to optimize its operations.

One of the key advantages of digital twin technology is its ability to provide real-time monitoring and analysis. By connecting the physical system to its digital twin, businesses can collect and analyze vast amounts of data in real-time. This allows for the identification of patterns, trends, and anomalies that may not be immediately apparent in the physical system alone. With this information, businesses can proactively address issues, make data-driven decisions, and optimize their processes for maximum efficiency.

Furthermore, digital twin technology enables businesses to simulate various scenarios and test different strategies without disrupting the physical system. By manipulating the virtual replica, businesses can explore different parameters, variables, and conditions to understand their impact on the system’s performance. This allows for the identification of optimal settings and strategies that can be implemented in the physical system to achieve desired outcomes.

The applications of digital twin technology are vast and diverse. In the manufacturing industry, digital twins can be used to optimize production processes, reduce downtime, and improve product quality. By monitoring the virtual replica, businesses can identify bottlenecks, inefficiencies, and potential failures in real-time, allowing for timely interventions and improvements.

In the energy sector, digital twin technology can be utilized to optimize the performance of power plants, wind farms, and other energy generation systems. By simulating different operating conditions and scenarios, businesses can identify opportunities to increase energy efficiency, reduce emissions, and improve overall system reliability.

The healthcare industry can also benefit from digital twin technology. By creating virtual replicas of patients, doctors can simulate different treatment options, predict outcomes, and personalize care plans. This can lead to more accurate diagnoses, optimized treatment strategies, and improved patient outcomes.

Digital twin technology is not limited to specific industries or sectors. Its potential applications extend to transportation, logistics, construction, and even smart cities. By simulating real-world systems and processes, businesses can gain a deeper understanding of their operations, identify areas for improvement, and make data-driven decisions to optimize performance.

In conclusion, digital twin technology offers a powerful tool for enhancing industrial processes. By creating virtual replicas of real-world systems, businesses can gain valuable insights, monitor performance in real-time, and optimize operations for maximum efficiency. The ability to simulate different scenarios and test various strategies without disrupting the physical system allows for informed decision-making and continuous improvement. With its vast applications and potential benefits, digital twin technology is poised to revolutionize industries and drive innovation in the years to come.

Improving Efficiency and Performance through Digital Twin Simulations

Digital Twin Technology: Simulating Real-World Systems for Optimization

In today’s rapidly evolving technological landscape, businesses are constantly seeking innovative ways to improve efficiency and performance. One such solution that has gained significant traction in recent years is digital twin technology. By creating virtual replicas of real-world systems, digital twin simulations offer a powerful tool for optimization and problem-solving.

At its core, a digital twin is a virtual representation of a physical object, process, or system. It combines real-time data from sensors, Internet of Things (IoT) devices, and other sources to create a dynamic model that mirrors the behavior and characteristics of its real-world counterpart. This virtual replica allows businesses to monitor, analyze, and optimize their systems in ways that were previously unimaginable.

The applications of digital twin technology are vast and diverse. From manufacturing and healthcare to transportation and energy, industries across the board are leveraging this technology to improve their operations. By simulating real-world scenarios, businesses can identify potential bottlenecks, optimize processes, and predict outcomes with a high degree of accuracy.

One of the key benefits of digital twin simulations is the ability to identify and rectify inefficiencies in real-time. By continuously monitoring the virtual replica, businesses can gain valuable insights into the performance of their systems. This real-time feedback enables them to make informed decisions and take proactive measures to improve efficiency and productivity.

Moreover, digital twin technology allows for predictive maintenance, a game-changer in industries where downtime can be costly. By analyzing data from the virtual replica, businesses can detect anomalies and predict when maintenance or repairs will be required. This proactive approach not only minimizes downtime but also reduces costs associated with reactive maintenance.

Another advantage of digital twin simulations is the ability to test and optimize new ideas and strategies without disrupting the real-world system. By creating a virtual replica, businesses can experiment with different scenarios and assess their impact before implementing them in the physical world. This not only saves time and resources but also minimizes risks associated with trial and error.

Furthermore, digital twin technology enables businesses to gain a deeper understanding of their systems and processes. By visualizing data in a virtual environment, complex relationships and patterns become more apparent. This enhanced visibility allows businesses to identify areas for improvement and make data-driven decisions.

The potential of digital twin technology goes beyond optimization and efficiency. It can also be used for training and education purposes. By creating virtual replicas, businesses can provide realistic and immersive training experiences for their employees. This not only enhances their skills but also reduces the risks associated with on-the-job training.

In conclusion, digital twin technology offers a powerful solution for improving efficiency and performance in various industries. By creating virtual replicas of real-world systems, businesses can monitor, analyze, and optimize their operations in ways that were previously unimaginable. From identifying inefficiencies and predicting maintenance needs to testing new ideas and enhancing training experiences, the applications of digital twin simulations are vast and diverse. As technology continues to advance, it is safe to say that digital twin technology will play an increasingly important role in shaping the future of businesses worldwide.

Harnessing the Power of Digital Twins for Predictive Maintenance and Fault Detection

Digital Twin Technology: Simulating Real-World Systems for Optimization

Harnessing the Power of Digital Twins for Predictive Maintenance and Fault Detection

In today’s rapidly evolving technological landscape, businesses are constantly seeking innovative solutions to optimize their operations and improve efficiency. One such solution that has gained significant traction in recent years is digital twin technology. Digital twins are virtual replicas of physical systems or processes that enable real-time monitoring, analysis, and optimization. This article will delve into the power of digital twins in the context of predictive maintenance and fault detection.

Predictive maintenance is a proactive approach to maintenance that aims to identify and address potential issues before they result in costly downtime or equipment failure. Traditionally, maintenance activities were scheduled based on fixed intervals or reactive responses to breakdowns. However, this approach often led to unnecessary maintenance or unexpected failures. Digital twins offer a game-changing alternative by providing real-time insights into the health and performance of physical assets.

By creating a digital twin of a machine or system, businesses can continuously monitor its condition and performance parameters. Sensors embedded in the physical asset collect data, which is then fed into the digital twin for analysis. Advanced analytics algorithms can detect patterns, anomalies, and deviations from normal behavior, enabling predictive maintenance strategies. For example, if a digital twin of a turbine detects a slight increase in vibration levels, it can alert maintenance personnel to investigate and address the issue before it escalates into a major problem.

Fault detection is another critical aspect of optimizing system performance. Identifying and rectifying faults promptly can prevent costly breakdowns and ensure smooth operations. Digital twins excel in this area by providing a comprehensive view of the system’s behavior and performance. By comparing real-time data from the physical asset with the digital twin’s expected behavior, deviations and faults can be quickly identified.

The power of digital twins lies in their ability to simulate real-world scenarios and predict the impact of different variables on system performance. By running simulations on the digital twin, businesses can test various maintenance strategies, evaluate the effectiveness of different interventions, and optimize maintenance schedules. This proactive approach minimizes downtime, reduces maintenance costs, and maximizes asset lifespan.

Furthermore, digital twins enable remote monitoring and analysis, eliminating the need for physical presence at the asset location. This is particularly valuable in industries with geographically dispersed assets or in situations where access to physical assets is challenging. Maintenance teams can remotely access the digital twin, monitor performance, and make informed decisions based on real-time data.

The benefits of digital twin technology extend beyond maintenance and fault detection. They can also be leveraged for design optimization, process improvement, and even training purposes. By simulating different scenarios on the digital twin, businesses can identify design flaws, optimize processes, and train personnel in a safe and controlled environment.

In conclusion, digital twin technology is revolutionizing the way businesses approach maintenance and fault detection. By creating virtual replicas of physical assets, businesses can continuously monitor performance, predict maintenance needs, and detect faults in real-time. The ability to simulate real-world scenarios and optimize system performance offers significant advantages in terms of cost savings, efficiency, and asset lifespan. As technology continues to advance, digital twins are poised to become an indispensable tool for businesses across various industries.In conclusion, Digital Twin Technology is a powerful tool that allows the simulation of real-world systems for optimization purposes. It enables organizations to create virtual replicas of physical assets, processes, or systems, providing valuable insights and data for analysis and improvement. By leveraging this technology, businesses can enhance operational efficiency, reduce costs, and make informed decisions to drive innovation and competitiveness. Digital Twin Technology has the potential to revolutionize various industries, including manufacturing, healthcare, transportation, and energy, by enabling predictive maintenance, performance optimization, and risk mitigation.