Sustainable waste handling is critical today; anaerobic digestion systems have changed everything. These new techniques have changed how we deal with organic waste, which is suitable for each of the surroundings and the economic system.

Anaerobic digester systems use herbal biological approaches to show organic waste into biogas and biofertilizers. They do that while specializing in performance and making acceptable use of assets. These steps referred to as anaerobic digestion, are now not the simplest way to cut down on the quantity of trash in landfills; however, they also produce beneficial things such as industrial power plants and fertilizer, which are full of vitamins. In addition to helping with waste management, these systems are becoming extra, not unusual, as a way to get clean energy.

By making biogas, we can use it to create strength and heat, which reduces our reliance on fossil fuels and facilitates combat weather exchange. Anaerobic Digester System makes organic fertilizer a sustainable choice over chemical fertilizers, making the soil healthier and less harmful to the environment.

This piece will discuss the many benefits of anaerobic digester systems and how they could assist with waste management. We will even discuss how they could help the surroundings and make the future more sustainable.

The importance of waste management

You can not say enough about how important it is to handle waste well. Here are some essential reasons why managing trash is necessary:

Protection of the surroundings: Recycling and nicely disposing of trash help defend the environment and decrease pollution. When humans do not take care of trash, it can pollute the air, water, and land, which is horrific for ecosystems and those’s fitness.

Resource Conservation: Reusing and recycling substances saves energy, herbal sources, and the effort and time required to get and deal with new raw materials.

Landfill Space Preservation: Many areas’ landfills are complete, but decreasing trash, recycling, and throwing things away correctly can help them last longer and reduce the need for brand-new ones.

Greenhouse Gas Reduction: Managing trash in ways like composting and accumulating methane from landfills can reduce greenhouse fuel pollutants by a massive amount, which enables slowing down weather alternates.

Public health: Good trash management stops the spread of diseases by keeping rodents, insects, and other pests that carry diseases from having places to breed. If you do not care for your trash, germs can grow.

Benefits for the economy: Waste management creates jobs in the recycling, processing, and collection industries. It can also save cities and towns money by cutting cleanup costs and dumping fees.

Quality of Life and Aesthetics: Recycling and proper trash removal keep neighbourhoods clean and attractive, raising the quality of life for everyone there.

How can we reduce water shortage?

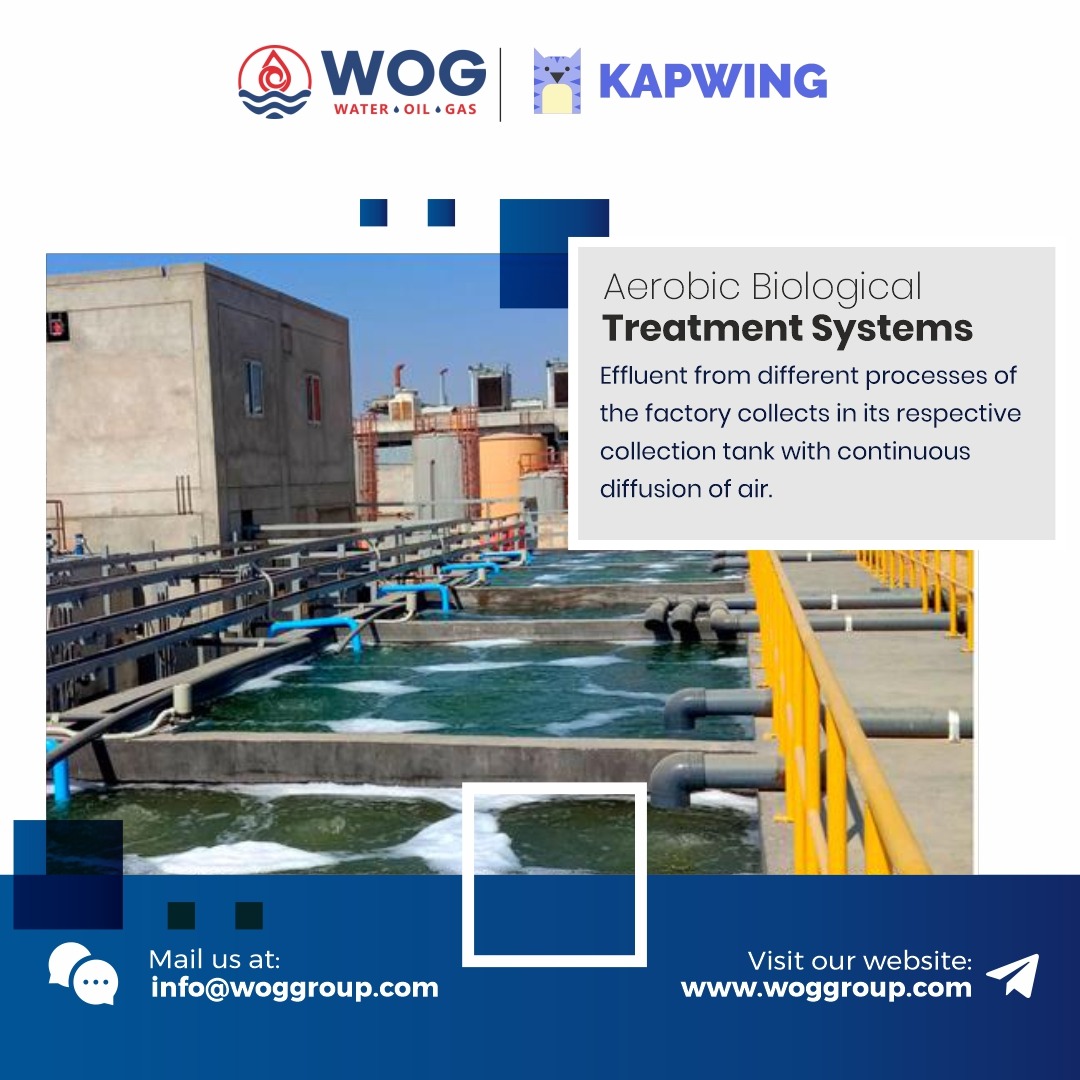

There are ways to clean sewage or wastewater to be put back into the water cycle. This is called wastewater treatment. Putting the wastewater back into the water recycling does not change the world much. A wastewater treatment centre is where the treatment takes place. The right wastewater treatment plant handles both types of wastewater; methods for treating wastewater from homes and businesses differ. There is either a different system for treating industrial wastewater or a sewage treatment plant that controls industrial process wastewater. All businesses are legally required to follow the rules and laws about industrial discharge, so an effluent treatment plant is an integral part of any business.

Industrial wastewater treatment is needed for food, chemical, paper and pulp companies, nuclear and thermal power, laundry, pharmaceutical, mining, iron and steel, and other industries. Home, business, and farm use are the three main types of businesses that create wastewater. These wastewaters contain many organic and inorganic chemicals. Extra nutrients dumped into the water cause minerals and nutrients to build up, which lowers the amount of oxygen in pools of water.

Goals of Treating Industrial Water

It is essential to handle process water treatment so that germs do not grow, which can hurt animals, plants, and trees if not stopped. To help clean up the earth, we have given millions of rupees to projects in India. The main goal of an industrial water treatment plant is to make water safe for people to use and reuse. Businesses can make money by using clean water in different ways during production. Not only does water carry chemicals, but it also brings many harmful substances. The water that factories dump into the earth contains dangerous chemicals. Leaving it out in the open is risky. The industrial water treatment device will free the water of chemicals and other harmful substances.

Types of waste suitable for anaerobic digestion

Anaerobic digestion is a process in which organic waste is broken down by microorganisms without oxygen, producing biogas (primarily methane and carbon dioxide) and a nutrient-rich digestate. The types of waste that are generally suitable for an Anaerobic Digester System include:

-

Agricultural waste:

- Manure from livestock (e.g., cattle, pigs, poultry)

- Crop residues (e.g., corn stover, wheat straw)

- Energy crops (e.g., maize, sorghum, switchgrass)

-

Food waste:

- Leftover food from households, restaurants, and food-processing facilities

- Fruit and vegetable waste

- Cooking oils and fats

-

Industrial waste:

- Wastewater sludge from municipal and industrial treatment plants

- Organic waste from food processing industries (e.g., dairy, slaughterhouses, breweries)

-

Municipal solid waste:

- Organic fraction of household waste (e.g., food scraps, yard waste)

- Paper and cardboard

-

Other organic waste:

- Sewage sludge from wastewater treatment plants

- Organic components of landfill waste

- Lignocellulosic biomass (e.g., wood, energy crops)

The critical factors in choosing appropriate waste for an Anaerobic Digester System are the organic remember content material, carbon-to-nitrogen (C/N) ratio, and the presence of inhibitory substances. The feedstock must have a balanced C/N ratio between 20:1 and 30:1 to ensure ideal microbial increase and biogas production.

The Wastewater Treatment plant will smooth up water from many specific types of organizations. Chemicals, textiles, and manufacturing companies are all part of this. For instance, the wastewater remedy answer technique will cope with each organic and inorganic pollutant and all the different contaminants from an Effluent Treatment Plant. The authorities now also make guidelines about how businesses can put off their waste because it’s been regarded for a long time for hurting the surroundings. So, treating effluent water is critical in many fields. It cleans the water using specific methods and removes all harmful substances.