The tin plate market plays a crucial role in various industries due to its unique properties and wide range of applications. This press release provides a comprehensive analysis of the current price movements, trends, and forecasts for tin plate across different regions including Asia, Europe, North America, Latin America, and the Middle East & Africa. By examining the factors influencing these trends, stakeholders can gain valuable insights into the market dynamics and make informed procurement decisions.

Request For Sample: https://www.procurementresource.com/resource-center/tin-plate-price-trends/pricerequest

Definition

Tin plate, a thin steel sheet coated with a layer of tin, is primarily used for its corrosion resistance, malleability, and ability to form an excellent barrier to air and moisture. This material is extensively utilized in the manufacturing of food and beverage cans, electronic components, and various industrial products. The tin coating provides both protection and a surface that can be easily soldered or welded, making tin plate an essential component in many production processes.

Key Details About the Tin Plate Price Trend

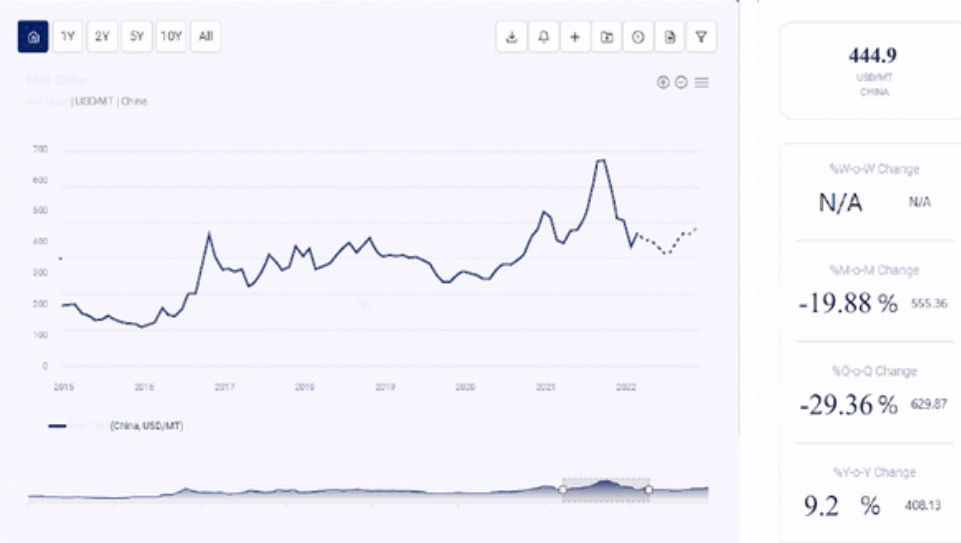

The price trend of tin plate is influenced by a multitude of factors, including raw material costs, production processes, supply chain dynamics, and global demand. Over the past few years, the tin plate market has experienced significant fluctuations in price due to changes in these influencing factors.

-

Raw Material Costs: The cost of raw materials, particularly steel and tin, plays a pivotal role in determining the price of tin plate. Any changes in the price of these base materials directly impact the overall cost of tin plate production. For instance, a surge in steel prices due to increased demand or supply chain disruptions can lead to a corresponding rise in tin plate prices.

-

Production Processes: Technological advancements and innovations in production processes can affect the cost and quality of tin plate. Efficient production methods that reduce waste and improve output can help stabilize or reduce prices. Conversely, disruptions in production, such as equipment failures or labor strikes, can lead to price increases.

-

Supply Chain Dynamics: The supply chain for tin plate is complex and involves multiple stages from raw material extraction to final product delivery. Factors such as transportation costs, import/export regulations, and geopolitical tensions can influence the supply chain and, subsequently, the price of tin plate.

-

Global Demand: The demand for tin plate is driven by its applications in various industries, including food and beverage, electronics, and packaging. Changes in consumer preferences, economic conditions, and industrial growth rates across different regions impact the global demand for tin plate. For example, a growing demand for canned food products in Asia can lead to increased tin plate prices in the region.

Industrial Uses Impacting the Tin Plate Price Trend

Tin plate’s versatility and protective properties make it indispensable in several industrial applications, which in turn affect its price trend.

-

Food and Beverage Industry: The largest consumer of tin plate is the food and beverage industry, where it is used to manufacture cans and containers. The demand for tin plate in this sector is influenced by factors such as population growth, urbanization, and changing dietary habits. For instance, an increase in the consumption of canned food products in North America and Europe has driven up the demand for tin plate, leading to price increases.

-

Electronics Industry: Tin plate is also used in the electronics industry for its excellent solderability and corrosion resistance. The rapid growth of the electronics sector, particularly in Asia, has heightened the demand for tin plate, contributing to price volatility. Innovations in electronic devices and the expansion of production facilities in countries like China and India further impact the tin plate market.

-

Packaging Industry: In addition to food and beverages, tin plate is widely used in the packaging industry for products such as aerosols, paint cans, and decorative containers. The demand for durable and recyclable packaging solutions has boosted the use of tin plate, particularly in Europe and North America. Environmental regulations and consumer preferences for sustainable packaging are key factors influencing this trend.

-

Automotive Industry: The automotive industry uses tin plate for various components due to its durability and resistance to corrosion. The growth of the automotive sector, especially in emerging markets like Latin America and the Middle East, has increased the demand for tin plate. Economic conditions, production rates, and technological advancements in the automotive industry significantly impact tin plate prices.

Key Players

The tin plate market is characterized by the presence of several key players who influence market dynamics through their production capacities, technological advancements, and strategic initiatives. Some of the prominent players in the tin plate market include:

-

ArcelorMittal: As one of the largest steel producers globally, ArcelorMittal plays a significant role in the tin plate market. The company’s extensive production facilities and focus on technological innovation help it meet the growing demand for high-quality tin plate.

-

Nippon Steel Corporation: Nippon Steel is a leading manufacturer of tin plate, known for its advanced production techniques and commitment to quality. The company’s strategic investments in research and development enable it to produce tin plate that meets diverse industry requirements.

-

JFE Steel Corporation: JFE Steel is another major player in the tin plate market, offering a wide range of products to cater to various industrial applications. The company’s emphasis on sustainability and efficient production processes has helped it maintain a competitive edge in the market.

-

Tata Steel: Tata Steel is a key producer of tin plate, particularly in the Asian market. The company’s integrated steel production facilities and focus on innovation allow it to supply high-quality tin plate to industries such as food and beverage, packaging, and electronics.

-

POSCO: POSCO is a prominent player in the tin plate market, with a strong presence in Asia and other regions. The company’s advanced production capabilities and strategic partnerships have enabled it to expand its market share and meet the growing demand for tin plate.

Conclusion

The tin plate market is influenced by a complex interplay of factors including raw material costs, production processes, supply chain dynamics, and global demand. Understanding these factors and their impact on price trends is crucial for stakeholders in making informed procurement decisions.

Contact Us:

Company Name: Procurement Resource

Contact Person: Christeen Johnson

Email: [email protected]

Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA