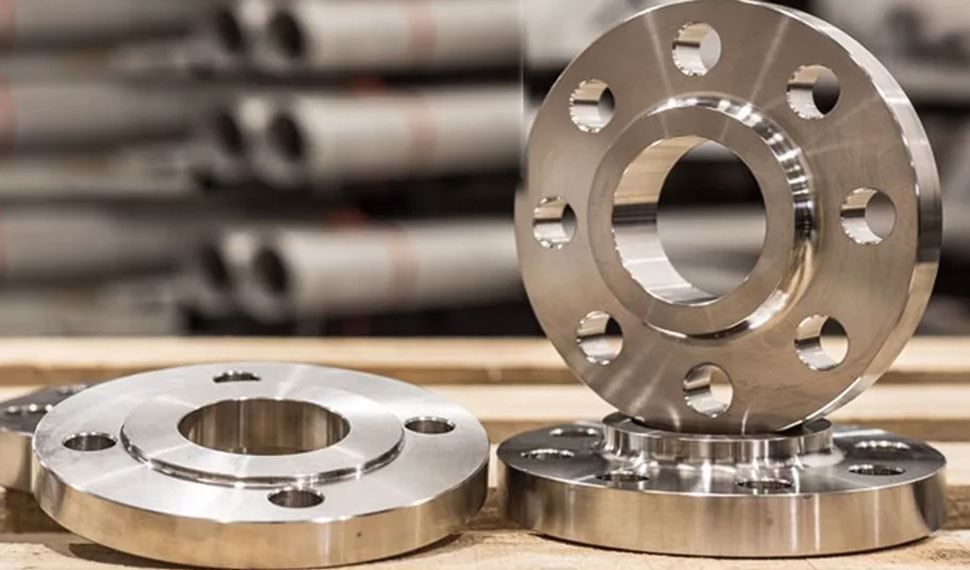

In the realm of industrial engineering and construction, few materials boast the versatility, durability, and reliability of stainless steel. Among its various grades, Stainless Steel 304L emerges as a standout choice, celebrated for its corrosion resistance, formability, and weldability. Within this robust alloy, Stainless Steel 304L flanges play a pivotal role, serving diverse applications across a spectrum of industries. In this comprehensive guide, we delve into the myriad uses and advantages of Stainless Steel 304L flanges.

Understanding Stainless Steel 304L:

Stainless Steel 304L is a low carbon variation of the widely acclaimed Stainless Steel 304. The “L” in its designation denotes its low carbon content, typically around 0.03% or lower. This modification enhances the material’s corrosion resistance in welded structures, making it suitable for applications where sensitization to intergranular corrosion is a concern. Stainless Steel 304L exhibits excellent formability, machinability, and weldability, rendering it indispensable in various industrial settings.

Properties of Stainless Steel 304L Flanges:

Stainless Steel 304L flanges inherit the exceptional properties of the alloy, making them an ideal choice for critical applications. Some key properties include:

-

Corrosion Resistance: Stainless Steel 304L flanges offer superior resistance to corrosion in a wide range of environments, including acidic, alkaline, and chloride-rich conditions. This corrosion resistance makes them suitable for use in chemical processing plants, water treatment facilities, and marine applications.

-

High Temperature Performance: Stainless Steel 304L flanges maintain their mechanical properties and corrosion resistance at elevated temperatures, up to approximately 1700°F (927°C). This thermal stability makes them suitable for applications involving high temperatures, such as heat exchangers, furnace components, and exhaust systems.

-

Strength and Durability: Stainless Steel 304L flanges exhibit excellent mechanical properties, including high tensile strength, toughness, and impact resistance. This ensures their durability and reliability in demanding operating conditions, minimizing the risk of failure and downtime.

-

Ease of Fabrication: Stainless Steel 304L flanges are easy to fabricate using common manufacturing techniques such as machining, forming, and welding. This facilitates the production of customized flange configurations to meet specific project requirements, enhancing flexibility and efficiency.

Applications of Stainless Steel 304L Flanges:

The versatility and resilience of Stainless Steel 304L flanges make them indispensable across a wide range of industries and applications, including:

-

Piping Systems: Stainless Steel 304L flanges are commonly used in piping systems for connecting pipes, valves, and fittings. Their corrosion resistance and leak-tight seal make them suitable for handling fluids and gases in chemical processing, food and beverage, pharmaceutical, and petrochemical industries.

-

Pressure Vessels: Stainless Steel 304L flanges are employed in the construction of pressure vessels and tanks for storing and transporting corrosive substances such as acids, alkalis, and solvents. Their robust construction and corrosion resistance ensure the integrity and safety of the vessel under varying pressure and temperature conditions.

-

Construction and Infrastructure: Stainless Steel 304L flanges find applications in construction and infrastructure projects where corrosion resistance and structural integrity are paramount. They are used in structural components, bridges, railings, and architectural features, enhancing the longevity and aesthetics of the built environment.

-

Oil and Gas Sector: In the oil and gas industry, Stainless Steel 304L flanges are utilized in pipelines, offshore platforms, and refineries for connecting piping systems and equipment. Their corrosion resistance and durability make them suitable for withstanding the harsh environments encountered in oil exploration, production, and refining processes.

In Conclusion:

Stainless Steel 304L flanges represent a cornerstone in industrial engineering and construction, offering unmatched corrosion resistance, mechanical strength, and versatility. From chemical processing plants to infrastructure projects, their myriad applications underscore their significance in ensuring safety, efficiency, and reliability across diverse industries. As technology advances and new challenges emerge, Stainless Steel 304L flanges are poised to remain at the forefront, driving innovation and progress in the world of engineering and construction.